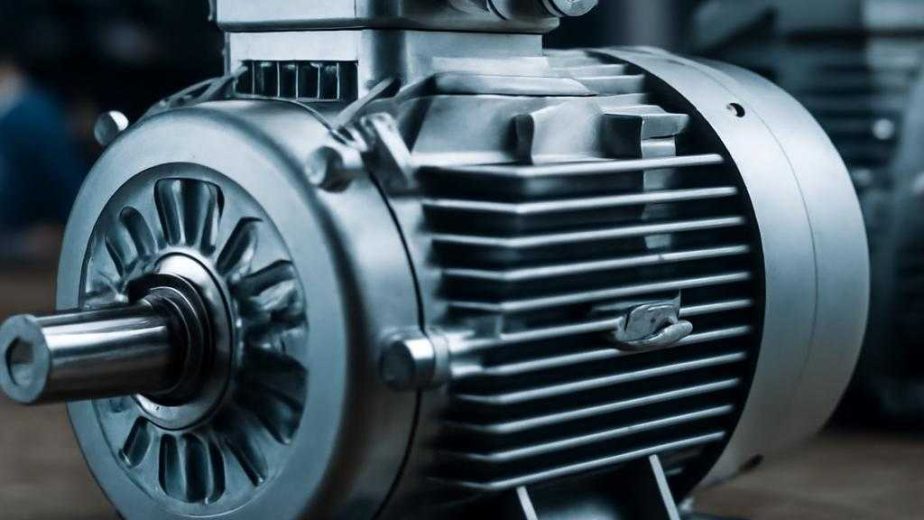

I’ve worked on many projects where the right choice of drive equipment made a measurable difference; when you need a dependable unit, consider this electric motor that combines documented performance with solid supplier support.

Practical considerations before committing

If you’re about to upgrade or specify new hardware, you should check a few essentials — don’t rush the decision. Here are some things you’ll want to verify:

– Environmental rating (dust, moisture, temperature) to pick an appropriate enclosure.

– Load profile and duty cycle so the drive matches real operational demands.

– Access to spare parts and local service to minimise downtime.

Also, take a look at the detailed ranges and options for electric motors to compare efficiencies and mounting variants before finalising the spec.

From an objective standpoint, the best results come when teams follow a staged approach: test, tune, then scale. He who manages maintenance will often advise running a small pilot, tracking thermal and current behaviour, and documenting everything. A simple three-step plan:

1. Run a pilot installation and collect operational data.

2. Adjust protection and control parameters based on measurements.

3. Roll out gradually and implement scheduled preventive maintenance.

For technical datasheets, product comparisons and supplier contacts, visit https://vyboelectric.com/. Be optimistic but thorough — the right preparation pays off in reliability and lower lifecycle costs.